Description

Buy Hanger Shot Blasting Machine from JX Abrasives Manufacturer in China, energy saving, efficiently remove of burrs and scales, increase surface roughness.

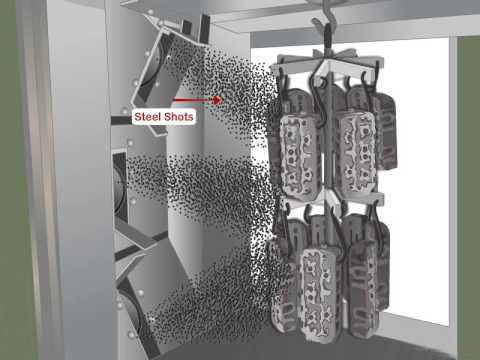

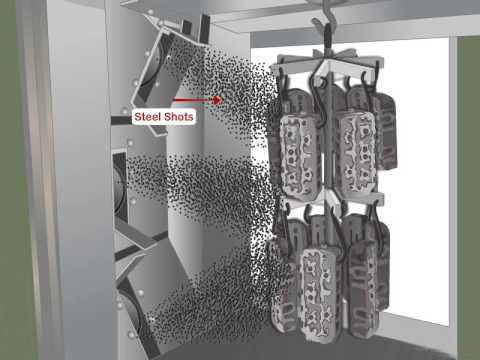

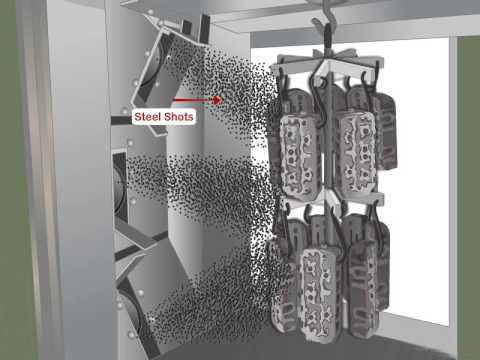

Hanger shot blasting machine is mainly used for casting. structural, non-ferrous alloy parts and other parts of the surface cleaning, shot blasting cleaning machine of this series at a single hook, double hook-type, lifting and not. Lifting style and many other . It has the advantages of no pit, compact structure, and high productivity.

Typical Applications:1. Removal of mill and forge scale as well as rust.

2. Removal of burrs and scales.

3. Removal of moulding sand.

4. Increase of surface roughness.

5. Shot peening to increase fatigue strength.

Machine Details:

This machine is not a standard machine, any parameters can be customized according clients’ requirements, so any further information please contact with us, our skilled engineer team will give you the most professional and cost-effective solutions.

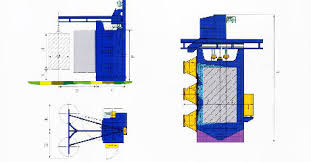

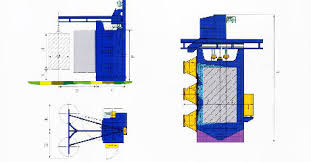

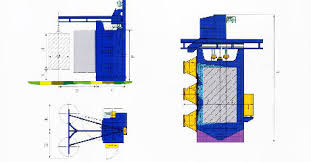

Technology Parameter(Customized is available): | Hanger Shot Blasting Machine |

| Item | Unit | DX376 | DX378B | DX378C | DX3710 | DX3720 | DX3730 | DX3750 | DX37100 |

| Max. weight of cleaning | kg | 500 | 600 | 800 | 1000 | 2000 | 3000 | 5000 | 10000 |

| Abrasive flow rate | kg/min | 2*200 | 2*200 | 2*250 | 2*250 | 3*250 | 3*250 | 4*250 | 4*250 |

| Ventilation capacity | m3/h | 5000 | 5000 | 5000 | 5000 | 9000 | 11000 | 14000 | 16000 |

| Lifting amount of elevating conveyor | t/h | 24 | 24 | 30 | 30 | 45 | 45 | 60 | 75 |

| Separating amount of separator | t/h | 24 | 24 | 30 | 30 | 45 | 45 | 60 | 75 |

| Max overall dimensions of suspender | mm | Ø600*1200 | Ø700*1200 | Ø1000*1600 | Ø1200*1800 | Ø1400*2200 | Ø1600*2300 | Ø1800*2500 | Ø3000*3000 |

These Type of Machines Consist of Under Mentioned Parts:1. Main Blast Cabinet with inspection Door.

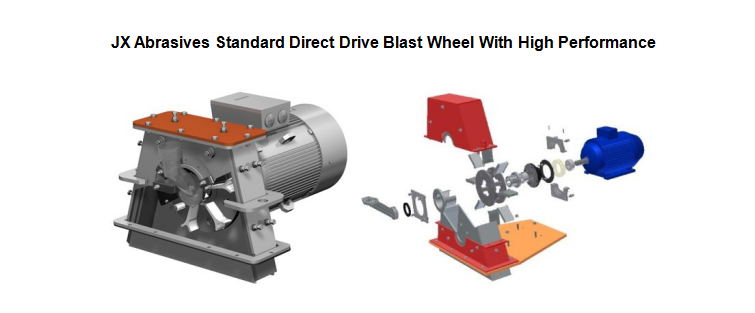

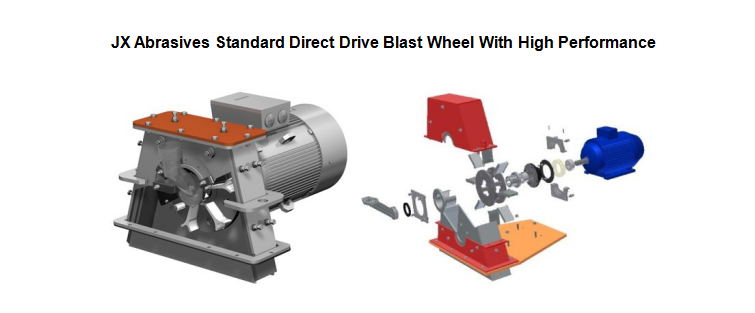

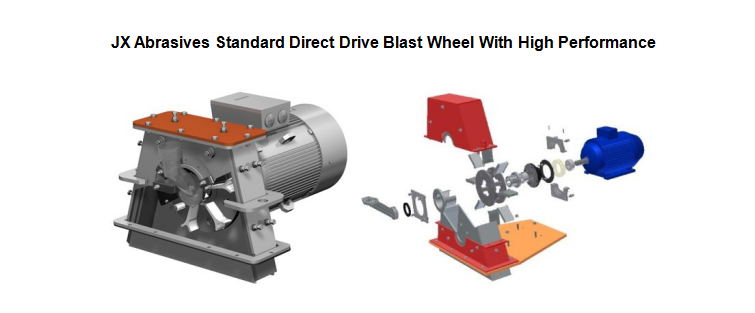

2. Blast Wheel Units with Drive Mechanism.

3. Abrasive circulation unit.

4. Bucket Elevator unit.

5. Abrasive Separation/Cleaning system with Storage Hopper.

6. Dust Collector with Cleaning Mechanism.

7. Roller Conveyor system at Inlet & Outlet Side.

8. Control Panel with PLC Control System.

Minimum Order Quantity: 1

1 Pack contains : set